Introduction and Structure

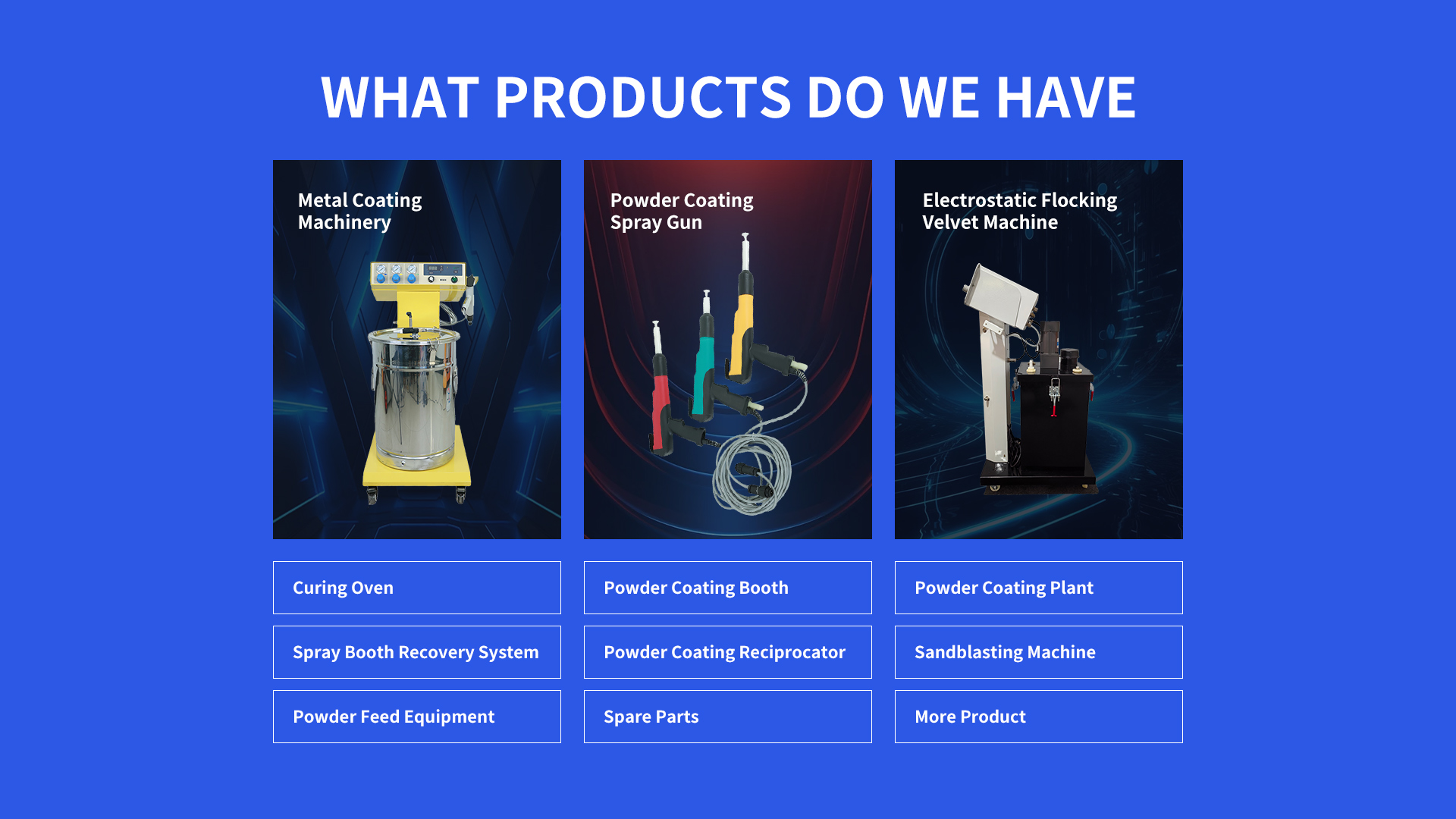

An Electrostatic Powder Coating Gun is mainly composed of a powder - feeding mechanism, often a hopper - like structure with a flow - control valve. The core part is the electrostatic charging unit, which charges the powder as it passes through. This charged powder adheres better to the grounded workpiece. The gun also has a spray nozzle in various sizes for different spray patterns, and a trigger - operated control system for regulating powder flow.

Application Scenarios

Automotive factories use it to coat car bodies and parts, achieving a durable and smooth finish. Metal furniture manufacturers rely on it to coat frames and components, enhancing their appearance and durability. In the electronics industry, it's used to coat metal enclosures of devices for protection and a sleek look.

Equipment Prices

Basic

Electrostatic Powder Coating Guns for small - scale use are around 1500. Mid - range models with better - quality components and more precise electrostatic control cost 5000. High - end industrial - grade guns with advanced features can be over $10000.

Correct Usage

Before use, connect the gun to the powder - feeding system and electrostatic generator properly. Adjust the electrostatic voltage and powder - flow rate according to the workpiece material and size. Hold the gun perpendicular to the workpiece, about 15 - 20 cm away, and move it steadily. After use, clean the gun and powder - feeding system to prevent powder residue.

Selection Tips

Consider your production volume. High - volume production requires a high - end gun with fast powder - flow capabilities. Evaluate the types of workpieces; complex shapes may need a gun with adjustable spray patterns. Also, set a budget that aligns with your long - term production plans.

Safety Precautions

Wear a dust mask, safety goggles, and gloves. Work in a well - ventilated area to avoid powder - related hazards. Ensure proper grounding for the electrostatic system to prevent electrical accidents.

Rationality Analysis

The electrostatic charging boosts powder adhesion, reducing waste. Adjustable settings allow for customization according to different workpiece requirements. It's a reliable choice for various powder - coating needs.

Q&A

Q: What to do if the powder coating is uneven?

A: Check the electrostatic voltage and powder - flow rate. Also, ensure the gun movement is consistent.

Q: Can different powder types be used?

A: Yes, but clean the gun and powder - feeding system thoroughly between powder changes.

Q: How often clean the electrostatic charging unit?

A: Clean it every few uses to maintain performance.

Q: What if the powder doesn't spray out?

A: Check for blockages in the powder - feeding system and the gun nozzle.

Q: Can the control panel be upgraded?

A: It might be possible. Check with the manufacturer for compatibility first.

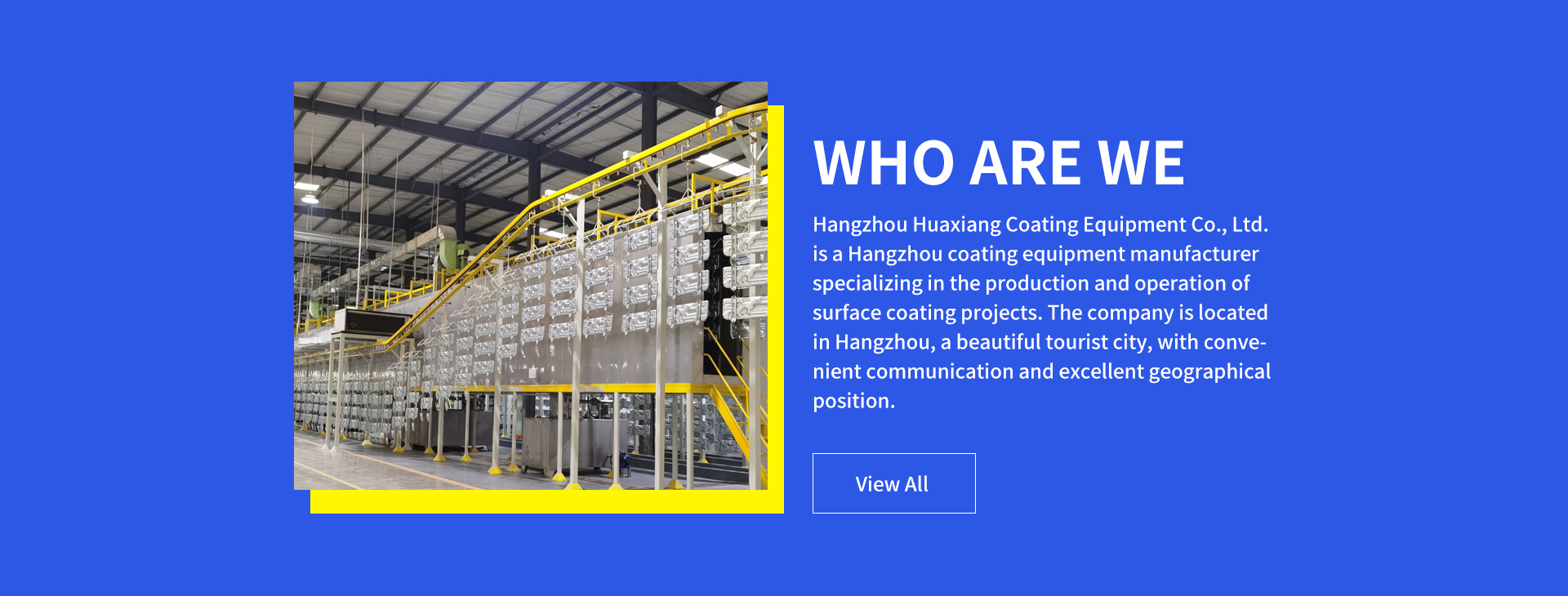

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com